| ~~~[ Contents ]~~~ “C90S Unleashed” by Angel Marinov ( March 15, 2010 ) |

|

- 01. You are at the right place!

02. What will happen if I follow this article?

03. C90S and Asus Support Policy

04. My System is Dead! Then What?

05. Where the Story Begin

06. Analysis & Agenda

07. Video Adapter Replacement ( the choice )

- • NVidia the world's famous 8600M

• NVidia 9600M GT 512M DDR3

• NVidia Quadro FX 770M 512M DDR3

• ATI Mobility Radeon HD 3650 512M DDR2

• ATI Mobility Radeon HD 4650

- 08. Preparation

- 09. Documentations

10. Drafts ( Video Heatsink “ASME” )

11. Hardware Tools

-

|

- 12. Mods – Implementation

- •• Video Heatsink “ASME” ( the BEST in the world )

•• South Bridge Heatsink

•• North Bridge Heatsink

•• BIOS 1002A

•• CPU Intel E7500

•• WiFi Atheros AR9280

•• RAM G.Skill F2-6400CL5D-4GBSQ

•• Fans

•• PSU Toshiba PA3717U-1ACA

- 13. NVidia Free C90S ( Results )

14. Software ( BIOSes & Drivers, ATI Drivers, Tests )

15. FAQ

16. Links

17. Thanks

18. Conclusion

19. Forum

"C90 Unleashed"

|

|

01. You are at the right place! Be calm and don’t worry!

Welcome to “C90S Unleashed”!

You own one of the best systems in the world. Thanks to Asus in C90S we are delighted to use the amazing video adapter “NVidia 8600M (G84)” and that’s why this article exists. There are two treats for the C90S’s healthy – “NVidia 8600M (G84)” and the User!

If your system is still working my personal advice to you is to replace the world’s famous 8600M. In a case that C90S has problems the odds a cause for that to be 8600M is nearly 100%. When it’s failed you have two choices - to throw the C90S or to follow this article. The wise one is the first one and you have from me “Good luck and all the best!”

In another case you are not alone and this article is for you. We can and we’ll do it!

02. What will happen if I follow this article?

Tip: See Also section “NVidia Free C90S ( Results )”

Your system will be up and running and will not work only when is turned off. C90S will be better than it was thanks to your work and the magic of the knowledge. The things are not difficult to be implemented. Don’t be afraid, be calm and stay focused, open your mind, think, dream. Your imagination is one of the most powerful human qualities that brings to you ideas and makes miracles.

You have to choose between two video adapters at the moment – “NVidia 9600M GT 512M DDR3” and “ATI Mobility Radeon HD 3650 512M DDR2”. If you are a gamer 9600M is for you. Until now there isn’t information about problems with 9600M. My personal choice is HD3650 and I’ll explain why in section “Video Adapter Replacement”. From mounting point of view the both video adapters are nearly identical. There are 2 differences which I’ll consider in section “Mods/ Video Heatsink”.

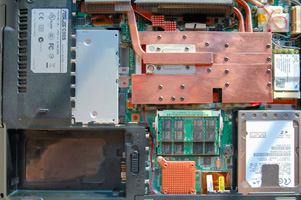

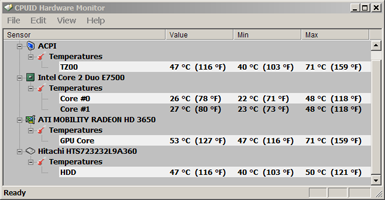

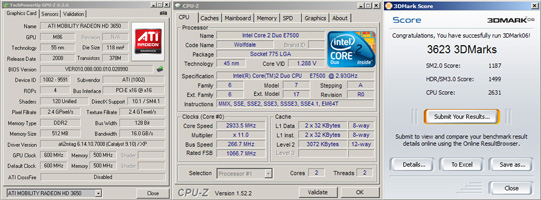

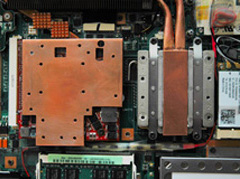

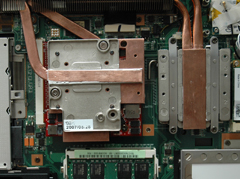

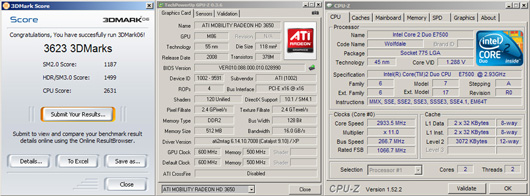

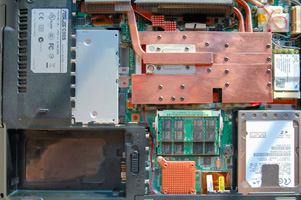

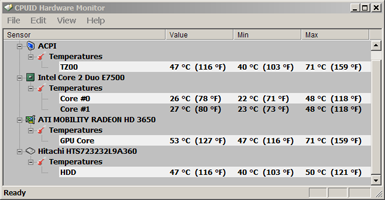

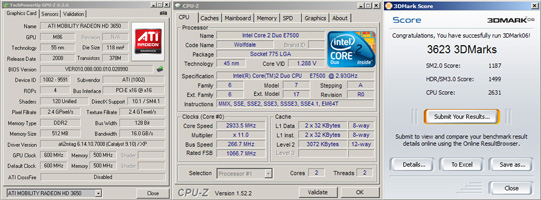

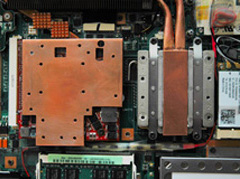

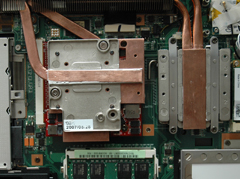

Here you are a C90S’s pictures with applied 5 Base mods - Video Heatsink, North & South Bridge, CPU E7500 & BIOS 1002A and GPU & CPU information. These 5 mods set I’ll call “Base Mod”. The temperatures on the second picture are after running stress tests "Prime95 25.11" (CPU) and "ATITool 0.27 Beta 4" (GPU) for 72 hours each and an ambient temperature of 25 ºC.

03. C90S and Asus Support Policy

From technical point of view C90S is unique and incredible laptop from 2007. In the time period October, 2007 – August, 2009 it works 24h per day without any freeze or restart nearly 2 years. C90S was one of the best reliable and stable systems for me. As an assembler Asus have all my respect and gratitude for C90S!

Asus is a correct business partner according to user’s agreement. No doubt about that!

I don’t like Asus support policy and I’m not an Asus supporter! C90S is my last Asus product.

A rhetorical question: “What is that ‘Support of a product’?”

04. My System is Dead! Then What?

One day on August 2009 I was surprised with a BSOD. After turn off and turn on, the screen on the system was filled with strange lines during the POST and after that. Windows showed an error related to NVidia driver before to switch in graphics mode. On the next restart the screen was entirely white and no POST. My system was dead and useless.

The main suspect was NVidia. I was out of warranty and I found only one place in US with an 8600M in stock. Thanks to Marc from www.macrecycling.com my system was back again.

05. Where the Story Begin

During the time in my search for 8600M I found a lot of information about unusually highest rate failures of this video adapter. I was terrified and realized how reliable will be my system. In front of me was the choice – to make my C90S NVidia Free or to throw it. I took the decision to save my C90S thanks to NightWalker’s work “Asus C90S MXM graphics card upgrade tutorial” on his NightWalker's domain.

Articles related to 8600M:

Question: Is this equation is true?

Asus C90S + NVidia 8600M = TROUBLES

My Answer: Definitely YES. “Why?”

1) Asus - Bad Cooling Design

2) Nvidia

- Bad Chips Design

Then we have the beauty:

Bad + Bad = C90S + Double Troubles

Let imagine the next:

Changed Thermal Design + ATI VGA = Quiet & Cool C90S

Is that is possible?

“Everything you can imagine is real.”, Picasso

I have no intention to argue with the artist.

06. Analysis & Agenda

“We can't solve problems by using the same kind of thinking we used when we created them.”

Albert Einstein

Here I recalled something! A rhetorical question: “Who is John Atanasoff?”

Every computer is a computer system consisting of many different components at different levels and layers connected each other. It’s essential to understand that definition when you have to deal with any software or hardware computer problem. Don’t forget the USER!

C90S is a low powered desktop put in the shape of a laptop, which is the source of thermal and power consumption problems. To deal with the thermal problem we need to understand the physical nature of processes (physics) and a little bit of mathematics to make some calculations and simulations.

The cooling design is based on dynamic air flow. It’s obvious why. From thermal point of view constant air flow is a better solution ("Why?"). Copper’s CPU & GPU heatsinks, better copper’s heatpipes are good decisions in right direction. Inappropriate use of heatpipes is one of the weaknesses in C90S thermal design.

We have to care for some important heat sources – CPU, GPU, South Bridge, North Bridge, HDD and DDR.

The die temperature of contemporary Video DDR chips is 105 ºC. ATI’s video adapters have GDDR chips from the both sides of their PCB. Something very important is that GDDR temperature is considerably lower than GPU temperature. That’s why there is no need to cool with a heatsink GDDR chips from the back side of a VGA.

Remove and threw out any thermal tapes, pads, compounds from the laptop! Many manufactures are using thermal tapes or pads because it’s a chip solution. Most of the used stock thermal compounds are with a very low quality. For the best thermal conductivity always use a quality thermal compound. For laptops it’s essential. At the moment the best compound is Noctua NT-H1. Some compounds are dangerous if you are not careful (e.g. Arctic Silver 5 – slight electrical conductivity).

Lower the temp to extend the system’s life and to maintain higher performance.

Keep the temp under 50 ºC. Upgrade all bad components.

A rhetorical question: “What’s Graphene?”

The problem with the lost wireless network connection on battery is caused from a software conflict between Intel’s Driver & Application and the OS. In Windows the solution is named Atheros AR9280. It’s little boring never to lose a connection and always having 300MBits/s to any 801.11n router.

PSU is one of the most important parts from our equipment. Let use the better one - Toshiba 120-Watt Global AC Adapter PA3717U-1ACA. I’m using also Toshiba 75-Watt Global AC Adapter PA3468U-1ACA (Yes, 75W!). One of the reasons for Toshiba’s PSU is if you have professional audio equipment. Audio engineers and musicians know what I’m talking about.

Let’s make C90’s cooling in that way that to hear the sound of ours SSD Drives.

A rhetorical question: “Is there a connection between C90S and the zebra?”

Let see what we have to do. Here you are the agenda (Base Mods):

- Upgrade VGA MXM II

- Build & Mount a Copper Heatsink “ASME” (the BEST in the world, ETA: 6 hours)

- Use Thermal Adhesive "Arctic Alumina Premium Ceramic Thermal Adhesive"

- Use Thermal Compound "Noctua NT-H1"

- Upgrade VGA Drivers

- Upgrade South Bridge Heatsink with a Copper one "Enzotech SLF-1"

- Add Copper Heatsinks over North Bridge Copper’s Pipe

- Update BIOS version to the last BIOS 1002A (BIOS 1002A = BIOS 1002 + E7500 Support)

- Upgrade CPU with Intel E7500

- Upgrade WiFi with Atheros AR9280 (802.11n/a/b/g 300 Mbps, 2Tx2R MIMO)

- Upgrade WiFi Driver

- Upgrade RAM memory with G.SKILL Model F2-6400CL5D-4GBSQ or better

- Upgrade PSU with “Toshiba 120-Watt Global AC Adapter PA3717U-1ACA” or better

Warning! If you do that your system will work in next 5 years without a warranty. Oh, that's a shame! But there is another problem with C90S – GPU temperature will drop with ~20 ºC and your system will whisper to you.

07. Video Adapter Replacement

The procedure of removing and put it back of VGA is simple and well described in "C90 Disassembly Procedure" on page 2-7. Here you are some pictures and short information regarding their respective models.

NVidia world famous 8600M ( Specifications )

That is the face of the bad guy, the source of all my troubles.

NVidia 9600M GT 512M DDR3 ( Specifications )

This card works on C90S.

NVidia Quadro FX 770M 512M DDR3 ( Specifications )

There is information that this card works on C90S.

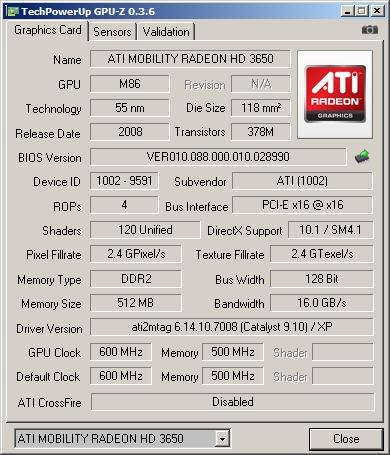

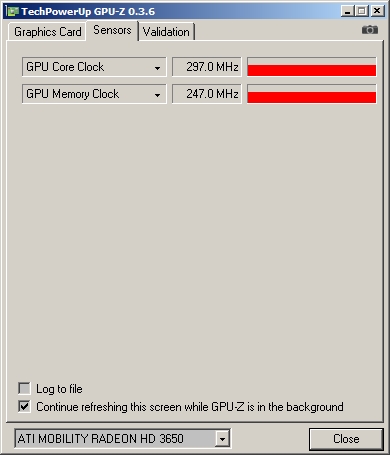

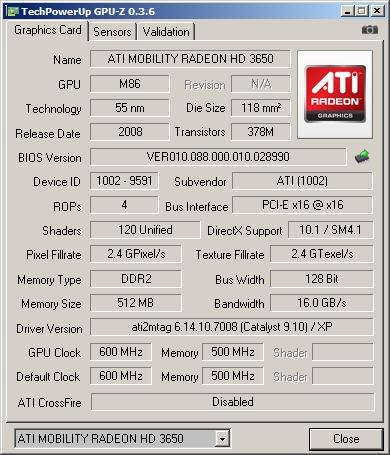

ATI Mobility Radeon HD 3650 512M DDR2 ( Specifications )

This card works at 100% on C90S. It's my choice for VGA. The software and hardware integration are perfect. No conflicts at any levels, stable with incredible balance and performance! The Blu-ray & HDMI are without any problem at any resolution (TV Sony KDL-46Z5500). Mobility HD 3650 is fully compatible at hardware, driver and application levels. Thanks AMD! Thank You, Kin Ho Chan!

ATI Mobility Radeon HD 4650 ( Specifications )

That card probably we can't see soon. It will be the best VGA for C90S.

08. Preparation

We have a need from some materials, documentations and hardware tools. All sizes are in millimeters (Metric)! Here you are the material's list (for exact details sizes check the drafts, all specifications are there):

09. Documentations

Manuals:

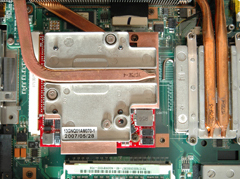

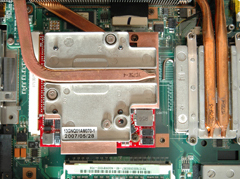

Motherboard Pictures:

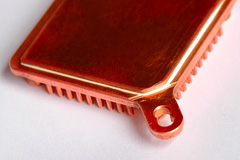

10. Drafts ( Video Heatsink “ASME” )

The quality of the drafts meets required standards on car industry and you can give them to any workshop from that industry (Renault, PSA, BMW, Honda, Ford, Chrysler …) without a technical explanation. The best way is to find out in your area some small workshop with CNC machines. Of course you can do it yourself in home environment as I did.

Here you are the links with professional drafts in two scales – (Manufacturer/Workshop) & (Model/Template/Do It Yourself). Also you have and the 3D model. The heatsink is tested on ATI Mobility Radeon HD 3650/512/DDR2 & NVidia 9600M/GT/512/DDR3.

Drafts / Manufacturer or Workshop

Models / Do It Yourself

3D Model

11. Hardware Tools ( Don’t forget to use safety glasses! )

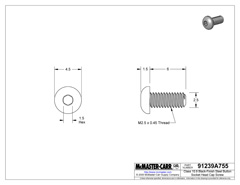

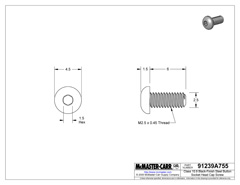

| Socket Cap Screw M2.5 x 6 mm |

Drill 2.05 .0807" |

Hex-Shank Drill Chuck |

|

|

|

| |

|

|

| Tap M2.5 x .45 mm |

Tap Wrench T-Handle Style, 0 - 1/4" (1.6-6.3mm) |

Prick Punch with Point Diameter 5/64" |

|

|

|

| |

|

|

| Metric Aluminum Unthreaded Round Spacer, 6mm Od, 2mm Length, M3 |

Standard Diamond Hand File, Flat, Medium (120) Grit, 0.25" Width |

Comfort-fit Wraparound Safety Glasses-xl Lens, Amber Lens |

|

|

|

| |

|

|

| Hacksaw |

Copper Sheet |

C-Clamps |

|

|

|

| |

|

|

| Spring Clamps |

Vernier Caliper |

Hex L-Key 1.5 mm |

|

|

|

| |

|

|

| Screwdriver Size #PH 1 |

Hammer |

Laser Paper 28lb / 105gr |

|

|

|

| |

|

|

12. Mods – Implementation ( "Please, Don’t Rush! Use safety glasses!" )

Try to sense and imagine the decision before its implementation. Untraditional thinking and ideas are extremely valuable for me.

Question: “Who’s the best designer (engineer) in the world?”

I would be happy if you achieve better results than me. You have this potential and I’m sure that you can!

••Video Heatsink “ASME” (the BEST in the world)

Tip: Before VGA mounting replace the thermal compound of the North Bridge and do the respective mod. See the “North Bridge Heatsink”

Step #1: Make the Heatsink “ASME”

Tip: With this song the things will be easily done – “Absolute Beginners”, David Bowie

There is two ways to make the Heatsink “ASME” – “Professional” and “Do It Yourself”.

The first one is the best one! Find out in your area some small workshop with CNC machines. Then give to that business all files from chapter “VGA Heatsink Drafts” in section “Drafts / Manufacturer or Workshop”. You are done, and ready for the next step - the Assembly!

If you choose to “Do It Yourself” then the drafts from chapter “VGA Heatsink Drafts” in section “Models / Do It Yourself” are for you. We will follow the next steps:

1) Print it without shrink or zooming

2) Stick the model to a copper sheet

3) Mark all points

4) Cut & Drill without any measuring

5) You have the perfect heatsink

6) Repeat the same for the GPU<=>CPU bridge parts

7) VGA Thermal Module Assy - Assembly

If you can’t to do this you steel have the option to take the “Professional” way. If that is a problem for you too, then don’t waste your time and buy another system! I wish you good luck and all the best! Thanks for your attention!

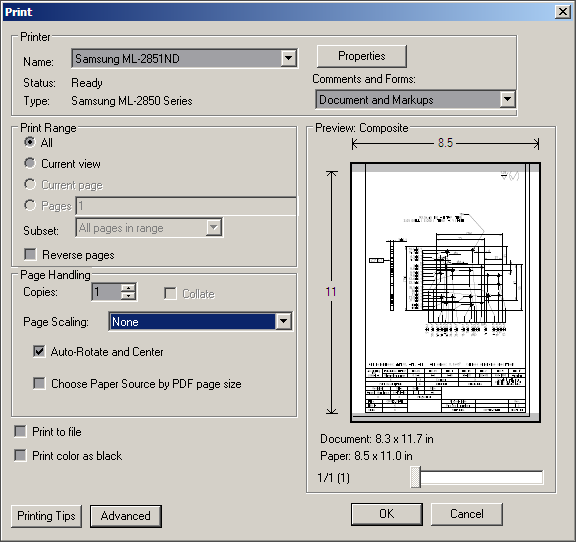

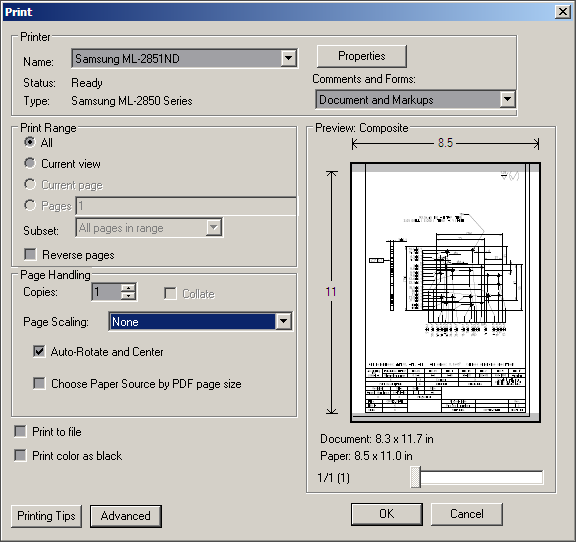

Print it without shrink or zooming. Instructions how to print the model:

Tip: Use Quality Laser Paper 28lb / 105gr/m

1) Download & Open pdf’s files Heatsink or Heatsink’s Outline (“Models / Do It Yourself”)

2) Print without shrink or zooming (Page Scaling: None)

3) Make sure that your print is correct, check the distance between holes 1-2-3-4 (Heatsink’s Outline Model), must be exactly 41 mm.

4) After you have all heatsink’s details from a paper you can put them on your system for a check.

Stick the model to a copper sheet. From the printed page cut the model via outlines. Use a glue to stick it on the corresponding copper sheet (watch the thickness, in this case 3mm).

Mark all points. Use the center punch and hummer to mark all the holes.

Cut & Drill without any measuring (or Drill & Cut what you preffer).

- Use safety glasses!

- Use a “Drill 2.05 (.0807")” in “Hex-Shank Drill Chuck” (from chapter “Hardware Tools”) to drill all holes

- Make the threads with a “Tap M2.5 x .45 mm” in “Tap Wrench T-Handle Style, 0 - 1/4" (1.6-6.3mm)”

- Drill the holes A & B (the hole B is ATI's related) too with their respective drills

- Use a hacksaw to cut the heatsink

- Clean the edges slowly and carefully with “Standard Diamond Hand File, Flat, Medium (120) Grit, 0.25" Width”

- For finishing use a Sandpaper Sheet “Fine/180” or finest one (it’s better)

- Screw and unscrew 3 times in every hole a new screw fully to check and clean the threads

- Use a vacuum cleaner to clean the heatsink and the work space

You have the perfect heatsink. Use a tooth brush and tooth paste for final cleaning of the heatsink. Now wash it with worm water and left it to dry.

Repeat the same for the GPU<=>CPU bridge parts. Don’t forget to clean carefully every detail!

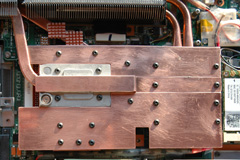

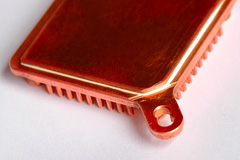

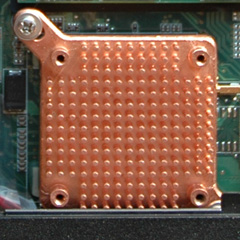

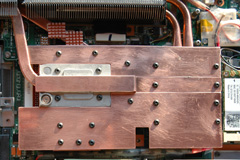

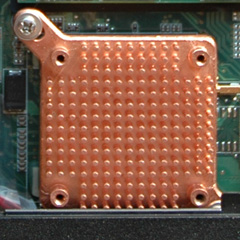

Now your parts must look better than mine because I have a prototype. Here you are the pictures of the prototype parts:

VGA Thermal Module Assy - Assembly. The detail “GPU<=>CPU Strip2” consists of molded “VGA Thermal Module Assy” and Strip #2. Cleanse very carefully the surfaces with “Isopropyl Alcohol”. To stick these two parts together use the thermal adhesive “Arctic Alumina Premium Ceramic Thermal Adhesive”. Follow the product directions and use “Spring Clamps”.

Here you are the pictures of the VGA Assy:

Pictures of the Assembled Heatsink “ASME”:

Step #2: Attach the Heatsink “ASME” to the VGA

For this purpose we will follow the next steps (don’t forget to use safety glasses):

1) Make Copper Pads GDDR

2) Make ATI Spacers (Aluminum)

3) Testing & Adjustment

4) Attach the Heatsink “ASME” to the VGA

Make Copper Pads GDDR. The pad’s size is (14.5 x 11 x 0.8~0.78). Use a hacksaw to cut 4 pads from a copper sheet with thickness 0.8 mm. I have two “ATI Mobility Radeon HD 3650 512MB DDR2” and the thickness of copper’s memory pads is different for every one of them. The reason for that is called tolerance. Every component (PCB, GPU, Memory chips. heatsink) and process (wave solder process, our actions) they have its own tolerances. That’s why I used for memory pads two copper’s sheets with thicknesses 1/32” (0.79375 mm) and 0.032” (0.8128 mm). In my case I filed 0.005 mm ~ 0.010 mm. Most manufactures use regular thermal pads because it’s fast and easy way to deal with the tolerances.

Tip: If you need to file use a sandpaper sheet “Fine/180”. Put the sandpaper over a smooth and flat surface. Then gently slide back and forth the copper’s pad with a finger over it. After every 10~15 moves, check the thickness with a caliper.

Make ATI Spacers (Aluminum). The spacer specification and link are on chapter “Hardware Tools”. There isn’t a spacer with height 1.7 mm. That’s why we’ll file the spacers (2 mm) to 1.7 mm with “Standard Diamond Hand File, Flat, Medium (120) Grit, 0.25" Width”. After every 10~15 file’s moves, check the height with a caliper. Spacers with 1.7 mm are fit perfect on my two ATI's VGA.

For “NVidia 9600M GT 512M DDR3” you'll need spacers (3 mm). The height is between 2.2~2.5 mm. You must find out yourself the exact height.

It’s possible to use washers as spacers if you are extremely careful and precise. I’m not recommending this approach! For me it was a raw way to determine spacer’s height.

Washers as Spacers (not recommended):

Testing & Adjustment. Here is the one of the biggest secret of our success. At this stage we have:

- 4x spacers (ATI’s 1.7 mm)

- 4x “Copper Pads GDDR”

- 4x “Socket Cap Screw M2.5 x 6 mm”

- 1x “Hex L-Key 1.5 mm”

- 4x “Flat Washers M2.7”

- 1x Heatsink “ASME”

We will follow the next steps:

1) Check & Adjust Spacer’s Height

2) Check & Adjust Copper Pads GDDR Thickness

Check & Adjust Spacer’s Height. Cover VGA heatsink’s mounting holes from both sides with “Super-Slick Teflon PTFE Tape” as is on the next two pictures. Then use something sharp to drill a hole (1.5~2 mm) in the tape (a big needle or punch). One of the washer’s sides is with sharp edges while another has well rounded slick edges. Take the screw and put it into a washer (sharp edges are directed to the screw’s head, see the pictures). Then gently start to screw the screw with the washer into the tape’s hole from VGA back side. When finish with all 4 screws and washers turn back the VGA and put spacers over the screws.

Take the heatsink “ASME” and VGA with one hand and with the “Hex L-Key 1.5 mm” in another start to screw with one rotation every screw one by one (screw 1 one rotation => screw 2 one rotation => screw 3 one rotation => screw 4 one rotation and do it again from the beginning until finish with very gentle force). Don’t rush and be careful here is no need from force. The good result is when GPU crystal is touching entirely the heatsink! That is the key to good thermal conductivity between GPU and heatsink which we’ll make perfect at the next step with "Noctua NT-H1".

In a case where GPU in not fully touch heatsink you will need to file their respective spacer(s) until achieve full touch (contact). Don’t try to correct the situation with stronger fastening - "That Is Wrong"! Don’t forget to fasten very gently!

VGA Back (screw+washer+tape+vga) & Front Sites(spacer+tape+vga+screw) pictures:

Check & Adjust Copper Pads GDDR Thickness:

1) Put a drop of thermal compound on all 4 memory chips

2) Firmly press copper’s memory pads over the chips

3) Attach the heatsink “ASME” to the video card

4) With a tooth stick try to push every pad gently. If someone of them slips freely then you needed more thickness

5) Check that GPU’s crystal is still touching entirely the heatsink. If not, then you need to file more copper’s memory pad(s). After that, repeat the procedure from the beginning. Remove previous compound with “Isopropyl Alcohol”

Attach the Heatsink “ASME” to the VGA.

Tip: Use the Magic – “Cat People (Putting Out Fire)”, David Bowie

“Cleaning! Cleaning! Cleaning!”. That’s the biggest secret for the heat transfer between GPU crystal and any heatsink.

Clean carefully your work place, remove any dust around you. Use a tooth brush and tooth paste for final cleaning of the heatsink “ASME” and the “Copper Pads GDDR”. Now wash all with worm water and left them to dry. Your hands must be clean too. Use vacuum cleaner for the VGA. Don’t touch with the plastic intake the PCB or its parts! Use “Cotton Swabs” with “Isopropyl Alcohol” to clean GDDR chips and GPU crystal. Repeat the procedure for the GPU in this way – use first wet (Isopropyl Alcohol) and immediately after that dry cotton swab to clean the GPU crystal. Do the same for the center of heatsink “ASME”. Both of them must be extremely clean without a speck of dust, greasy spots, greasiness and residue. Don’t touch them with fingers!

Now Follow the Final Steps:

- Put a drop of thermal compound on all 4 memory chips

- Firmly press copper’s memory pads over the chips

- Clean carefully top sides of the copper memory pads as already you know and wait 60 seconds

- Put a drop of thermal compound on all 4 copper memory pads

- Take a look at GPU crystal. If you decide cleanse it again

- Put a drop of thermal compound on the GPU crystal. On this stage the picture must look at like this:

- Attach the heatsink to the video card. Follow the procedure from “Check & Adjust Spacer’s Height”. Don’t forget to fasten very gently!

- Inspect very carefully the VGA with mounted heatsink “ASME”

- Clean the VGA with a vacuum cleaner

- Inspect it again very carefully from all sides. With a tooth stick push every spacer gently. If someone of them moves then gently fasten the respective screw(s). In front of you are the next pictures:

- Clean the VGA’s MXM II Slot and around with the vacuum cleaner

- You are ready to mount the VGA in our C90S. Do It!

- Attach the “VGA Assy” with 1x Original M2.5 x 3 and 4x M2.5 x 3 screws. Don’t forget that all 14 screws from GPU side are M2.5 x 3 mm! It's very important! Remember that!

It’s a time for a test drive. Start the engine and watch on your windshield for some POST messages or something else. If that is the case then you are ready to install the video drivers. Go to the section “Upgrade VGA Drivers” and install them. Check the temperatures, make some tests, ,…, and return to the section “Mount the GPU<=>CPU Bridge”.

If you can’t see anything on the screen then turns off the system. Please, do the next:

1) Remove PSU & Battery

2) Remove video adapter and carefully inspect both the MXM slot & the VGA pins. Clean the pins with “Isopropyl Alcohol” and wait 1-2 minutes. Clean around the heatsink with a vacuum cleaner too

3) Then assemble things again and try to start the system

If your system is still not working then something is wrong with the VGA. Try to check it again (including disassembling of the heatsink).

You have to find out where is the problem!

Step #3: Mount the GPU<=>CPU Bridge

For this purpose we will follow the next steps:

1) CPU Thermal Module Assy Mod

2) Mount the GPU<=>CPU Bridge

CPU Thermal Module Assy Mod. Make the 5 screws on Strip #2 a little loose, in that way we can move the strip back and forth. The movement is around a half millimeter. Attach another 2 Strips (#1 & #3) in the same way as Strip #1. Arrange (justify) the strips from the right CPU side. When they are in the line, fasten the screws gently. Use a pencil to mark the centers of the 8 holes on the “CPU Thermal Module Assy”. Then remove the Strips and “CPU Thermal Module Assy”.

Don’t forget to use safety glasses! Put the “CPU Thermal Module Assy” on smooth and flat surface. Be careful for the heatsink and copper pipe! Use gently a hummer with the center punch to mark the holes, because the material is very soft. Use a “Drill 2.05 (.0807")” in “Hex-Shank Drill Chuck” (from chapter “Hardware Tools”) to drill slowly all holes. Then make the threads with a “Tap M2.5 x .45 mm” in “Tap Wrench T-Handle Style, 0 - 1/4" (1.6-6.3mm)”. Screw and unscrew 3 times in every hole a new “M2.5 x 6 mm” screw fully to check and clean the threads. Use a vacuum cleaner to clean the “CPU Thermal Module Assy” and the work space.

Cleanse very carefully the surfaces (the two CPU’s copper pipes & CPU’s Rising Strip) with “Isopropyl Alcohol”. To stick these two parts together use the thermal adhesive “Arctic Alumina Premium Ceramic Thermal Adhesive”. Follow the product directions and use “Spring Clamps”. Here you are a picture:

Cleanse the CPU and “CPU Thermal Module Assy” with “Isopropyl Alcohol”. Then use a thermal compound and mount the “CPU Thermal Module Assy”.

Mount the GPU<=>CPU Bridge. Attach the Strips and fasten the screws in next order:

1)

GPU Side

2)

CPU Side

3) Fasten the Screws

GPU Side:

Tip: Don’t forget that all 14 screws from GPU side are M2.5 x 3! It's very important! Remember that!

- “VGA Assy” namely Strip #2 with 4x M2.5 x 3 screws and 1x Original M2.5 x 3, loosely

- Strip #1 with 3x M2.5 x 3 screws, loosely

- Strip #3 with 6x M2.5 x 3 screws, loosely

CPU Side:

Tip: Don’t forget that all 8 screws from CPU side are M2.5 x 6! It's very important! Remember that!

- Strip #1 with 2x M2.5 x 6 screws, loosely

- Strip #2 with 2x M2.5 x 6 screws, loosely

- Strip #3 with 4x M2.5 x 6 screws, loosely

Fasten the Screws. After Strips alignment, fasten gently all screws. Your final view must be better than mine picture:

Important Options:

1) When finish all mods use a very small part of "Noctua NT-H1" over GPU Heatsink & CPU Rising Strip before attaching the strips for better thermal conductivity and easy disassembling next. If you put too much thermal compound then disassembling will be difficult! In that case try to slide (move) back and forth the strip(s) before removing.

2) Use "Loctite 243 Threadlocker" to prevent our fasteners from loosening

Now you own the best heatsink “ASME” in the world. You did it yourself!

I'm waiting from you world records. Do it!

History

Here you are some pictures of GPU heatsink with HD3650, GPU & CPU Rising Strips & Before them:

Step #4: Upgrade VGA Drivers

My choice for VGA is “ATI Mobility Radeon HD 3650 512M DDR2” (378 Million Transistors & 55nm Technology). I'm using XP 32-bits with SP3 and ATI’s video driver “ATI Mobility HD 3650 Drivers 9.10” for XP 32-bits. You must install Video & HDMI drivers. Here you are the installation's steps:

1) Download "ATI Mobility HD 3650 Drivers 8.6 & 9.10 for XP 32-bits"

2) Extract the archive with the drivers

3) Install Video: run the file “ATI Mobility HD 3650 Drivers 8.6 & 9.10 for XP 32-bits\9-10\Driver\setup.exe”

4) Install HDMI: run the file “ATI Mobility HD 3650 Drivers 8.6 & 9.10 for XP 32-bits\9-10 HDMI Audio\setup.exe”

5) After a correct installation your “Device Manager” must be clean from warnings. Check it!

If you have different OS download the last driver’s versions from ATI's web site. After that unlock driver support for HD3650 Mobility with the tool "Mobility Modder 1.2.1.0", which modify some .inf files and you are ready to install it.

Question: "Why we need to unlock driver support for HD3650 Mobility"?

For those of you with another VGA look at manufacture’s WEB site for drivers.

••South Bridge Heatsink.

Use safety glasses! Current mod require the next 2 steps:

1) Mod the heatsink from “Enzotech SLF-1 Forged copper 1100 Fan & Heatsinks”

2) Mount the new South Bridge Heatsink

Mod the heatsink from “Enzotech SLF-1 Forged copper 1100 Fan & Heatsinks”. Read "C90 Disassembly Procedure" on page 2-12 starting from point 6. To reach the “South Bridge Heatsink” we must to remove IO Bar first. Remove the fan from “Enzotech SLF-1 Forged copper 1100 Fan & Heatsinks” and take the heatsink (36.94 x 36.94 x 6.66). Use a hacksaw to cut a rising copper pad (33.3 x 33.3 x 1.7). Cleanse the edges slowly and carefully with “Standard Diamond Hand File, Flat, Medium (120) Grit, 0.25" Width”. Use a tooth brush with tooth paste for final cleaning of the heatsink and the rising copper pad. Wash both with worm water and left them to dry.

Cleanse very carefully the surfaces (the rising pad & heatsink bottom) with “Isopropyl Alcohol”. To stick these two parts together use the thermal adhesive “Arctic Alumina Premium Ceramic Thermal Adhesive”. Follow the product directions and use “Spring Clamps”. The size of our new heatsink is (36.94 x 36.94 x 8.36). Here you are a picture:

Mount the new South Bridge Heatsink. Put a drop of thermal compound on the “South Bridge” chip and mount the heatsink (2x M2 x 6 screws and 2x M2.7 flat washers). Here you are pictures with assembled IO Bar:

“Ooops! You Dit It Again!”

••North Bridge Heatsink

Tip: Replace the thermal compound every year!

This mod is simple. In the same time it's very important because the North Bridge is serious source of heat. Here we'll do two things:

1) Mod the “North BridgeThermal Module Assy”

2) Change the thermal compound

Mod the “North BridgeThermal Module Assy”. We will use two Copper DDR Heatsinks (remove any tapes) to extend the surface of the North Bridge Copper Pipe. To remove North BridgeThermal Module Assy take a look at "C90 Disassembly Procedure" on page 2-8, point 4. After removing use a tooth brush with tooth paste for cleaning of the Copper Pipe and two Copper DDR Heatsinks. Wash all with worm water and left them to dry.

Cleanse again very carefully the surfaces (pipe & two DDR heatsinks) with “Isopropyl Alcohol”. To stick heatsinks to the pipe use the thermal adhesive “Arctic Alumina Premium Ceramic Thermal Adhesive”. Follow the product directions and use “Spring Clamps”. At the end you have the next picture:

Change the thermal compound. “Cleaning! Cleaning! Cleaning!”. Use “Cotton Swabs” with “Isopropyl Alcohol” to clean the North Bridge crystal. Repeat the procedure in this way – use first wet (Isopropyl Alcohol) and immediately after that dry cotton swab to clean the crystal. Do the same for the “North BridgeThermal Module Assy”. Both of them must be extremely clean without a speck of dust, greasy spots, greasiness and residue. Don’t touch them with fingers! Here you are a picture of the North Bridge:

Put a drop of thermal compound on the “North Bridge Crystal” and mount the “North BridgeThermal Module Assy”.

That's it!

••BIOS 1002A

The BIOS version 1002A supports Intel’s E7500 CPU (it’s a mod of original 1002). To update C90S with the last BIOS version 1002A follow the next steps:

1) Download BIOS “1002A” on .ISO image

2) Extract “C90S-Bios-ISO-1002A-1002.iso” file from the archive

3) Burn it on CD/DVD

4) Boot from the CD/DVD (press “ESC” key and choose “Boot from CD/DVD”)

5) Run “update.bat” (type without quotes at prompt and press “Enter”). It will start the Update Procedure for BIOS 1002A

Type on prompt:

A:\> update

Press “Enter”,

BIOS will be updated with version 1002A.

This CD/DVD contain also and BIOS version 1002. If you want

to update with 1002 just type on the prompt:

A:\> afudos /i1002.rom

6) Watch the screen. After the finish, restart your system

Now you have the last BIOS for C90S installed.

Bravo!

••Upgrade CPU Intel E7500

Tip: Choose the right E7500

Before this important upgrade first you must to update your BIOS with version 1002A. "How to do that?". Take a look at previous section “BIOS 1002A”.

At the moment there are 3 different versions of E7500. Two of them support “Virtualization Technology”. Make your choice and install the CPU. The procedure is simple and described in "C90 Disassembly Procedure" on pages 2-3 and 2-4. Here you are a picture on the CPU in C90S:

Use “Cotton Swabs” with “Isopropyl Alcohol” to clean the CPU and “CPU Thermal Module Assy”. Repeat the procedure in this way – use first wet (Isopropyl Alcohol) and immediately after that dry cotton swab to clean the CPU. Do the same for the “CPU Thermal Module Assy”. Both of them must be extremely clean without a speck of dust, greasy spots, greasiness and residue. Don’t touch them with fingers! Then use a thermal compound and mount the “CPU Thermal Module Assy”.

You have a cool & fast CPU for our C90S.

Thanks Intel!

••WiFi Atheros AR9280 ( Specifications )

If you want to have a reliable wireless connection in any mode then Atheros AR9280 (802.11n/a/b/g 300 Mbps, 2Tx2R MIMO) is the choice. This is the best WiFi card for me. Fast with good range and support of all standards. We will follow the next steps:

1) Hardware Installation

2) Driver Installation

Hardware Installation. To install the WiFi card follow the procedure in "C90 Disassembly Procedure" on page 2-6. The Atheros card supports a two-antenna-wire design. The U.fl. connectors on the top edge of the card are labeled as 1 (black arrow) and 2 (white arrow). These indicate which antenna lead (white or black) is to be connected to which connector button. Connect the white and black cables to the antennas connectors as they are on the picture:

The third cable (the grey one) must be isulate and stick with a tape to the modem.

Driver Installation. Download the driver “Atheros WiFi AR9280 7.7.0.456 for XP ( 32&64-Bits )”. Extract the archive and go to the “Device Manager => Network Adapters”. Choose our WiFi adapter with a right mouse click and select “Update Driver …”, after that point extracted driver folder. Press OK and installation will start. After the finish restart the system and enjoy!

It’s little boring never to lose a connection and always having 300 MBits/s to any 801.11n router.

Thanks Atheros!

••RAM G.SKILL F2-6400CL5D-4GBSQ

One of the most importing things is the RAM. When we have dual channel architecture as in C90S it's essential to have two identical DIMMs. That’s why we take the kit with two fastest 200-Pin DDR2 SO-DIMMs at 800MHz (PC2 6400) and timing 5-5-5-15. Except the speed another extra of this memory is a little bit of heat radiation. Here you are a picture:

It isn’t difficult to install the RAM. Follow the procedure in "C90 Disassembly Procedure" on page 2-4.

Thanks G.SKILL!

••Fans ( Specifications )

The cooling design is based on dynamic air flow. The fans in C90S are four good and powerful “Delta AFB0412VHB”. They cool two aluminum heatsinks attached to the three copper pipes – CPU, GPU and North Bridge. We have one fan for GPU & North Bridge and 3 fans for the CPU. Respectively they have different power sources and separate speed control. See the picture, white plug (CPU fans) and black plug (GPU fan):

A BIOS procedure(s) manages the fans according to different thermal conditions and CPU’s specifications. Fans management is not the same with different BIOS versions (“Why?”).

C90S has bad cooling design (it’s obvious), the source of all thermal problems. That’s why I designed “ASME”. If you follow my mods then required thermal policy for these mods perfectly much the thermal policy you already have in BIOS version 1002A (“Why?”).

Question: “Is that’s enough for the proper cooling?”

Answer: “YES! According to my thermal policy based on dynamic air flow the cooling is perfect!”

Question: “Is there a better way to cool C90S?”

Answer: “YES, it is! From thermal point of view constant air flow is a better solution ("Why?").”

C90S cooling based on constant air flow. We have a need from a constant power source. C90S offer us two for the case:

1) The Battery at constant 12.25V is not good decision as power source! I’m not recommending this approach! Something more it’s a wrong way! Don’t Do That!

2) The PSU or "Power Plug" near to the fan array at 19V is the right direction. I’m working on it and when I’m ready the solution will be here. Shortly, it’s a hardware implementation of a cooling solution based on constant air flow. It works only at 19V. When the power plug is “IN” we have the ability to switch between dynamic and constant cooling modes. Default state is dynamic. In a constant mode you can control fans voltage from 7V ~ 13V. In a case of missing AC power follows automatic switching to dynamic mode.

CAUTION: Don’t solder anything to your motherboard! Without a clear vision and understanding you’ll destroy any system. At this point YOU are the biggest threat with such “smart thinking” for the C90S’s healthy. Ask yourself “Are you deserve the C90S?”.

“Two things are infinite: the universe and human stupidity and I'm not sure about the universe.”

Einstein

••PSU Toshiba PA3717U-1ACA

PSU is one of the most important parts from our equipment. “Toshiba 120-Watt Global AC Adapter PA3717U-1ACA” is the best PSU for C90S. There isn’t a problem with the professional audio equipment. It runs cool and has long cables. Here you are a picture:

If you follow my way then your system will work also with the PSU "Toshiba 75-Watt Global AC Adapter PA3468U-1ACA". There aren’t problems with any network interface and attached peripherals.

Thanks Toshiba!

13. NVidia Free C90S ( Results )

Tip: See Also section “What will happen if I follow this article?”

My C90S:

- PSU: Original Asus 90W

- BIOS: 1002A

- CPU: E7500

- GPU: ATI Mobility Radeon HD 3650

- GPU Heatsink: “ASME” (the BEST in the world)

- Memory: 2 x 2G G.Skill / 800MHz

- HDD: 320G Hitachi / 7200 RPMs / 16M Cache

- OS’s: XP SP3 (32-bits) / Knoppix 6.0.1 (32-bits) / Fedora 10 (64-bits) / Solaris 10 (64-bits)

Don’t forget that the results are related to so call “Conditions (Normal)” mode. You will be in real trouble with “Conditions (High)” mode. Your problem is how to heat GPU. Here is a short info for modes Normal & High Conditions:

Some Results & Temperatures (Normal):

- I haven’t any freezes or restarts on battery mode or on PSU

- My system is working perfectly with any network interface and attached peripherals

- Uptime from ( 2009-November-05 )at ~ 40% CPU load

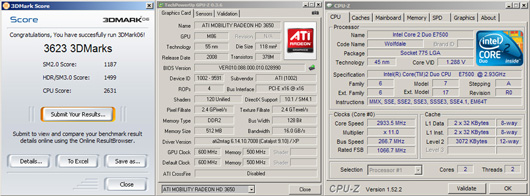

- 3DMark06: 3623

- Idle 2D: 49 ºC

- Load 2D: 53 ºC

- Load 3D (3DMark06): 66 ºC

- Load 3D (ATITools): 71 ºC

Conditions (High):

- Ambient temperature of 25 ºC ~ 28 ºC

- Without any mod of the C90S case

- Without cooling pads, additional fans or air conditioner

- Fans Noise (Idle Mode) ~ 35 dB-A at constant 12.25V

- Customized Hardware Fan Control at constant voltages (12.25/11.93/11.62/11.31/11.00/10.70/10.39/10.10/9.80/9.50/9.22/8.96)

- Without any kind of installed overclocking tools or antivirus

- Idle 2D: 35 ºC

- Load 2D: 36 ºC

- Load 3D (3DMark06): 49 ºC

- Load 3D (ATITools): 57 ºC

If someone think that temperatures are still high he’s right! There are 3 things we can do. One of them is my secret weapon “double diffuser”. And because it’s a secret I’ll say only that “Do you remember who is the world champion for 2009 and why in F1?”

Battery Performance:

My battery is the original one ( 6-Cell, 4800mAh ) from 2007. Here you are pictures:

27 Minutes Before Mods (October, 2007)

Equipment:

CPU: Intel Extreme X6800

GPU: NVidia 8600M / 512M / DDR2

HDD: Hitachi 200 GB / 7200 RPM / 16M Cache

WiFi: Intel 4965AGN

Screen: Max (brightness/contrast)

Actions:

- Listening to music (winamp)

- Reading PDF files (Acrobar Reader)

- Browsing Internet at 130 Mbits (Opera)

74 Minutes After Mods (March, 2010)

Equipment:

CPU: Intel E7500

GPU: ATI Mobility Radeon HD 3650 / 512M / DDR2

HDD: Hitachi 320 GB / 7200 RPM / 16M Cache

WiFi: Atheros AR9280

Screen: Max (brightness/contrast)

Actions:

- Listening to music (winamp)

- Reading PDF files (Acrobar Reader)

- Browsing Internet at 300 Mbits (Opera)

14. Software ( BIOSes & Drivers, ATI Drivers, Tests )

ATI Video Drivers & Tools

The video drivers are for XP 32-bits. I'm using XP 32-bits with SP3. You can download the last version for Windows 7 from ATI's web site. After that unlock driver support for HD3650 Mobility with the tool "Mobility Modder 1.2.1.0", which modify some .inf files. You are ready to install the video driver. You also have a need from HDMI support which is a separate driver. It's a part from my archive with 9.10 drivers. After a correct installation your Device Manager must be clean from warnings.

Atheros WiFi Driver

Testing Tools

Monitoring Tools

C90S BIOS Versions:

C90S BIOS Utilities

C90S Drivers

15. FAQ

Q) "Your drawings are ASME A4 and ISO? What is this world coming to?"

A) ASME is a standard which have nothing to do with "American Society of Mechanical Engineers". Tip: asus < ASME!

Q) “What are the considerations when bridging CPU and GPU heatsinks?”

A) Effectively using of CPU thermal assy.

Q) “Did you have to resolder your heat pipe, or did you just grind off the aluminum?”

A) Just grind off the aluminum. Some of you make a mistake when are bending C90S heatpipes (they have a specific internal structure) because in that way you are reducing capacity of heat transfer.

Q) “Does anyone know any places where I can buy plates of Copper?”

A) The best place for me in US is McMASTER-CARR. Here you are a link:

Q) “What purpose do the extra holes you cut into your heat spreader serve?”

A) On the next picture is my VGA heatsink prototype which I’m using right now. All temperature results are with this one heatsink.

The distance between holes 1-2-3-4 is 41 mm.

“B” hole is ATI related. I used also this hole to read GDDR memory chip temperatures.

“C” hole was to put an external temperature sensor to measure GPU temperatures.

Q) “Did you need spacers between the heatspreader and the card, … ?”

A) Yes. Spacers (Aluminum) Height: 1.70 mm. (ATI Mobility Radeon HD 3650 512MB DDR2). NVidia 9600M GT 512M DDR3 spacers are higher than ATI’s.

Q) “I have some questions related to your mode. Let me know where to find you.”

A) I’ll be glad to answer at all your questions. If you prefer you can use my e-mail ( Angel.Marinov@sineva.net ) with mail’s subject that contain “C90S:”.

Q) “Did you happen to have to do any vBIOS mods for your HD 3650?”

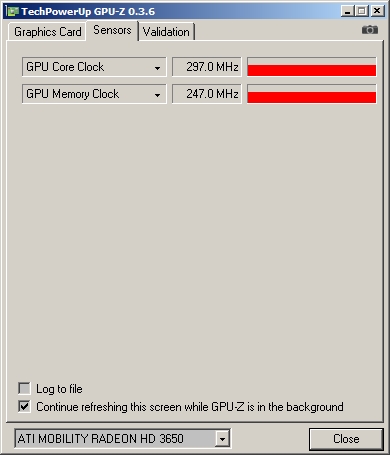

A) No, I’m not. Just plug & play. Here you are GPU-Z info from my ATI Mobility Radeon HD 3650 with 512MB DDR2.

Graphics Card & Sensors:

Q) “I've decided to buy a 3650 and some copper to start working on it but I can’t find the thermal padding used in the original post. Do I really need it?”

A) No, in the context of “ATI Mobility Radeon HD 3650 with 512MB DDR2”. My personal suggestion to you is to use (made by you) copper’s pads (14.5 x 11 x 0.8~0.78mm) as I do on the next picture:

Q) Can someone link me where I can get some good thermal padding if its really needed? Also about the aluminum spacer used on the mod, where can I get one as well?

A) In the US all you need is on:

Q) “ … what did you use for the heatsink backplate on your HD 3650 Angel?”

A) Nothing! The use of a backplate is a bad decision. The idea to attach a video heatsink in that way is unique. Here you are the picture you need:

Q) Where did you get those threaded screw mount things?

A) At www.mcmaster.com

Picture of Video Adapter Screw M2.5 x 6:

The 3D Model of the screw ( pdf, 469kb )

Q) “As for fastening the heatsink to the card to you just use a simple threaded bolt or what?”

A) The answer is in front of your eyes. Please look at the picture carefully:

Q) “If you could give me the exact links to both the exact screw model and bolt you used …”

A) Here you are the links to the screw (M2.5 x 6 mm) and tools you needed to make the holes:

Socket Cap Screw M2.5 x 6 mm:

Q) “… could you tell the score of hd3650 in 3dmark05/06, …”

A) The 3DMark’06’s score of “ATI Mobility Radeon HD 3650 512MB DDR2” is 3623.

Q) “Related to cooper pads, is it the height distance between the GPU and MEM chips only 0.8mm?”

A) I can’t measure exactly that clearance.

I have two “ATI Mobility Radeon HD 3650 512MB DDR2” and the thickness of copper’s memory pads is different for every one of them. The reason for that is called tolerance. Every component (PCB, GPU, Memory chips. heatsink) and process (wave solder process, our actions) they have its own tolerances. That’s why I used for memory pads two copper’s sheets with thicknesses 1/32” (0.79375 mm) and 0.032” (0.8128 mm). In my case I filed 0.005 mm ~ 0.010 mm. Then I used thermal compound Noctua NT-H1 from both sides of the pads. Most manufactures use regular thermal pads because it’s fast and easy way to deal with the tolerances.

Q) “I think there is still a small clearance between the pads and the RAM and Heatsink. Can this < .5 mm space be gapped by thermal compound on both sides?”

A) Yes, you can do that. In my opinion 0.5 mm is still big clearance. My suggestion is to check it in this way:

1) Put a drop of thermal compound on all 4 memory chips.

2) Firmly press copper’s memory pads over the chips.

3) Attach the heatsink to the video card.

4) With a tooth stick try to push every pad gently. If someone of them slips freely then you needed more thickness.

Some compounds are dangerous if you are not careful (e.g. Arctic Silver 5 – slight electrical conductivity).

Q) “I got 2mm THK Nylon spacers. How did you get 1.7mm spacers? by filing them down?”

A) Yes! I used a diamond file for that job. Here you are my file and spacers:

Metric Aluminum Unthreaded Round Spacer, 6mm Od, 2mm Length, M3

Standard Diamond Hand File, Flat, Medium (120) Grit, 0.25" Width

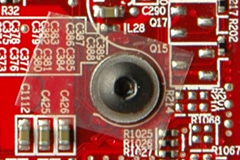

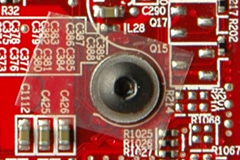

Q) What is the model of PLL chip:

A) It's "Cypress CY28551LFXC". Here you are a picture with the chip:

16. Links

Forum “C90S Unleashed” on Sineva.net:

Forum “C90S Unleashed”

WEB Site Dedicated to C90S:

WEB site “C90S Unleashed”

My spirit and motivation comes from human wisdom, art, music, poetry, literature and knowledge. My Philosophy is here, in the books:

Laoism: The Book of Lao Zi

www.sanmayce.com

www.laoism.cn

Question: “Who made the first trip to the Moon?”

17. Thanks

I would like to express my respect and gratitude to Mitko Petrov for his help with the magnificent drafts and 3D model.

Thank You, Mitko!

Special thanks to Sanmayce for his e-book “The book of Lao Zi”. This ancient Chinese Classic is one of the richest sources with human wisdom for me.

Thank You, Sanmayce!

18. Conclusion

The good companies must be honest with its clients. When someone makes a mistake it’s a good practice to admit the problem first.

Next is to do the best to fix it and after that to ask for an apology.

I’m not happy with my choice of Asus C90S. I’m very disappointed from Asus & NVidia, from a lack of attitude to their products in the context of Asus C90S. It’s a good example how to lose a customer as me.

I would like the current C90S condition was the condition when I bought it in 2007. Thanks to the mods my C90S is an amazing tool for me and I'm fully satisfied! My system is perfect (stable, cool, quiet) with incredible balance and performance! Picasso was right! I wish to anyone such system.

I’m feeling fantastic!

“When everyone in the world knows the beautiful as beautiful, ugliness comes into being; ~ When everyone knows the good, then the not good comes to be. ~ The mutual production of being and nonbeing, ~ The mutual completion of difficult and easy, ~ The mutual formation of long and short, ~ The mutual filling of high and low, ~ The mutual harmony of tone and voice, ~ The mutual following of front and back - ~ These are all constants. ~ Therefore the Sage dwells in nonactive affairs and practices the wordless teaching. ~ The ten thousand things arise, but he doesn't begin them; ~ He acts on their behalf, but he doesn't make them dependent; ~ He accomplishes his tasks, but he doesn't dwell on them; ~ It is only because he doesn't dwell on them, that they therefore do not leave him.”

Lao Zi

I wish to all of you to be better and better. Never lose your Dreams and Imagination!

Angel Marinov

Enjoy!

|